Products > Sleeves > Thermal / Flame & Fire Protection

Exhaust pipe protection sleeve - Engine & generators - personnel protection

High Temperature, Heat & Flame Resistant and Thermal Insulating - For Automotive / Truck / Bus / Marine / Military / Construction / Mining Vehicles

1100°F / 593°C Continuous Exposure: Higher Intermittent

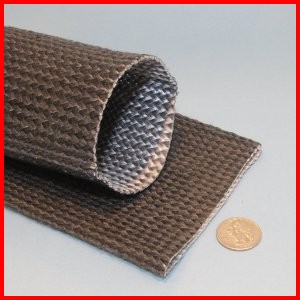

BlackMaxä Exhaust Pipe Sleeve is a high temperature and heat resistant fiberglass braided sleeve, fabricated from high quality type E fiberglass that will not burn and will withstand continuous exposure to temperatures of 1100°F / 593°C. With an acrylic saturant, this sleeve is easy to handle, and is designed to provide burn protection to personnel from casual contact to the exhaust piping risers on transport truck engines and on generator installations. Typically held in place with stainless steel band clamps.

This high temperature sleeve / heat resistant sleeve resists most acids and alkalis and is unaffected by most bleaches and solvents. It is highly flexible and conformable. The black color hides dirt and grime contamination.

The base fiber is manufactured to the specifications of ASTM D-578, ASTM committee D13, and subcommittee D13.18.

· Helps maintain exhaust gas temperatures in order to meet regulatory requirements.

· Knitted design allows for high conformability.

· Can be fabricated with apertures to accommodate brackets and mounting pads.

· Available in pre-cut or continuous lengths.

· Expandable and durable - provides ease of installation.

· Conforms to bends, elbows, flex sections and flanges.

· Suitable for Fixed Generators, Marine Engines and Generators, Automotive, Truck,

Bus, Construction and Mining equipment.

· Knitted design allows for high conformability.

· Can be fabricated with apertures to accommodate brackets and mounting pads.

· Available in pre-cut or continuous lengths.

· Expandable and durable - provides ease of installation.

· Conforms to bends, elbows, flex sections and flanges.

· Suitable for Fixed Generators, Marine Engines and Generators, Automotive, Truck,

Bus, Construction and Mining equipment.

Technical Specifications

Fiber Type: E Glass

Specific Gravity: 2.54-2.69

Breaking Tenacity: 1.71 gf/TEX. Std. 1.71 gf/TEX Wet

Effect of Heat: Will not burn; Retains 75% tensile at 343°C; Softens at 732-877°C; Melts at 1121-1182°C

Tensile Strength: 450,000-500,000 psi.

Effect of Acids and Alkalis; Resistance to acids is fair. Good resistance to most alkalis.

Breaking Elongation: 4.81% Std. 4.81% Wet

Elastic Recovery: 100%

Effect of Bleaches and Solvents: Unaffected

Average Stiffness: 2824.3 cn/TE